Concentration Measurement On Ball Mill Silica

Comparative Study on Improving the Ball Mill Process

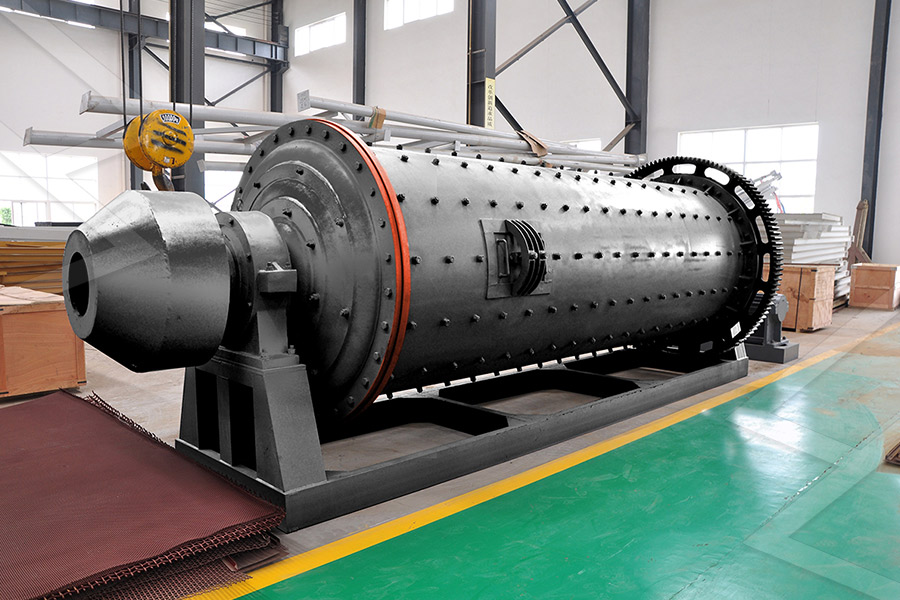

2021年2月19日 The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L while the optimum speed of the ball A hydrophobic silica fine powder is prepared by premixing a hydrophilic silica fine powder with a dimer diol siloxane or cyclic siloxane as a hydrophobizing agent, mixing them in a ball mill for concentration measurement on ball mill silica2018年6月1日 In this article the effect of grinding media size distribution and feed material particle size distribution (PSD) on the product fineness requirements were investigated A Effect of ball and feed particle size distribution on the milling 2019年3月1日 The three main parameters applied in this study are Ball to Powder weight Ratio (BPR), time milling process, and rotational speed (rpm) The materials used in the study was Parameter Optimization of Ball Milling Process for Silica

Intensified mineral carbonation of natural Canadian silicates

2023年9月1日 Ballmilling was shown to assist in intensifying mineral carbonation reactions by integrating milling and reaction unit processes into one, whereby the reactive surface area is 2021年6月30日 A process for twostage continuous silica extraction from rice husk was successfully developed using alkaline leaching and attrition ball mill methods The alkaline leaching conditions obtained in batch experiments were TwoStage Continuous Process for the Extraction 2019年12月13日 The experiment confirmation value particle size of silica sand can be accepted because the value is in the range of confidence intervals, figure 6 Figure parison of PAPER OPEN ACCESS Parameter Optimization of Ball 2023年1月12日 In this study, silica nanoparticles (SiO 2 NPs) were fabricated using a handmade ball mill as a novel, simple, rapid, costeffective, and green approach The sol–gel method was Facile, fast, and green preparation of highpurity and quality silica

.jpg)

Evolution of grinding energy and particle size during dry

2024年6月18日 In this paper, we report on a detailed experimental analysis of the longterm grinding behavior of silica sand as a model material in an oscillatory ball mill for a broad range 2019年8月1日 By comparison, the point load on the particles in ball mills is conducive to the attrition process (Bu et al, 2019b;Bu et al, 2020a) Abrasion and attrition result in rounder (more spherical Differences in dry and wet grinding with a high solid concentration 2019年3月1日 The materials used in the study was Bangka silica sand tailing, with an average size of D50: 267 µm, based on the measurement of Particle Size Analyzer (PSA) The results of signaltonoise analysis obtained the optimum parameter values in a row are: 100 rpm for milling speed parameter, 15: 1 for BPR parameter and 120 minutes for timemiling Parameter Optimization of Ball Milling Process for Silica2022年11月5日 Fuji et al reported that the powder surface can be activated by a mild ball milling treatment at very low rotation speeds without sufficient pulverization and silane coupling agents [17]The cleavages of siloxane bonds (Si–O–Si) on the silica particle surface could be confirmed because of the friction between the balls and particles even under mild milling, resulting in the Surface modification of silica powder by mild ball milling

Comparative Study on Improving the Ball Mill Process

2021年2月19日 The highgrade silica was milled in planetary ball mill and the selected samples were passed through washing, crushing, dehydrating, meshing and drying operations In addition, Taguchi developed a transformation of the repetition data to another value which is the measure of variation The transformation is the signaltonoise (S/N) ratio For the ballmilling, 18 g of the zeolite and ten alumina balls 20 mm in diameter were added to a cylindrical jar of 65 mm in diameter and 300 mL of volume The system was then coupled to the ballmill equipment and subjected to a transversal rotation at 400 rpm The mechanical treatment varied between 05, 1, 2, 4, and 8 h 22Impacts of ballmilling on ZSM5 zeolite properties and its 2023年6月17日 This study aims to elaborate on the production of a nanostructured FeSi alloy with varying silicon concentrations and how it can enhance the magnetic properties of the alloy In order to achieve this, the mechanical alloying technique was employed to create the nanostructured alloy After the mechanical ball milling process, the morphological, structural, Effects of silicon concentration on the magnetic and 2018年6月1日 Silica ore was used as the test material The experimental parameters that were kept constant in this investigation was the grinding media filling, powder filling and the mill rotational speed Dry batch milling tests were performed in a laboratory scale ball mill measuring 302 by 282 cm The mill specifications are given in Table 1 A Effect of ball and feed particle size distribution on the milling

.jpg)

(PDF) Pilotscale continuous biogenic silica extraction from

2023年9月26日 A twostage continuous process was developed for improved silica extraction from rice husk The twostage continuous process consists of attrition ball milling and alkaline leaching methods2023年1月12日 In this study, silica nanoparticles (SiO2 NPs) were fabricated using a handmade ball mill as a novel, simple, rapid, costeffective, and green approachFacile, fast, and green preparation of highpurity and quality silica 2020年10月1日 The energy efficiency of dry fine grinding process of powders dramatically declines with decreasing particle size, and represents a growing concern in various cuttingedge technical applications for pharmaceutical and cosmetic products, advancedceramics, and food industryIn this paper, we report on a detailed experimental analysis of the longterm grinding Evolution of grinding energy and particle size during dry ball 2022年8月1日 Grinding is an important and widely applied industrial process for decreasing the size of particles, and it has been most frequently carried out together with liquid medium to improve the efficiencyEffects of powder–liquid states on the grinding efficiency of silica

.jpg)

The effect of alumina contamination from the ballmilling of

2011年6月1日 Alumina is a common additive to silicabased ceramics and glasses Alumina and silica in stoichiometric ratios and at high temperatures form mullite, Al 4+2x Si 2−2x O 10−x, with x ranging between 02 and 09, depending on the formation temperature and atmosphere 6 It has been reported that alumina can prevent the devitrification of silica However, this is in common 2021年3月27日 Dry batchmillingtestswere performedin alaboratoryscale ball mill measuring 302 by 282cm The mill specifications are given in Table 1 A constant ball load of 20% was maintained in all the tests with a ratio of 05 for binary and 033 for trinary ball mix 21 Feed material preparation A quartz ore samplewas used in the experimental test Effect of ball and feed particle size distribution on the 2023年12月3日 Sustainability 2021, 13, 7350 2 of 11 stoves or boilers During burning, rice husk is oxidized, resulting in ash products This is the simplest method to obtain inorganic compounds from rice huskTwoStage Continuous Process for the Extraction of 2022年1月1日 On the other hand, the types of mills where the kinetic model was less applied were planetary ball mills (for mica and dolomite) (Matijašic and Glasnovic, 2009, Andrić et al, 2013), stirred ball mills (for quartz and nickel laterite) (Ma et al, 1998, Tong et al, 2013), and electromagnetic mill (for limestone) (WołosiewiczGłąb et al The effects on the grinding parameters of chemical,

.jpg)

Effects of slurry concentration and powder filling on the net mill

2003年11月1日 The tests covered a range of slurry concentrations from 30 to 55 vol% solid and fractional interstitial bed filling (U) from 03 to 175, at a fixed ball load (30% of mill volume) and 70% of 2020年4月4日 23 Preparation of calcinated silica microspheres based STF The cSiO 2 microsphere powders and ethylene glycol were added into the ball mill and then ground for 24h at room temperature to insure even dispersion of the microspheres Here, the ball mill is better than ultrasonic dispersion, magnetic stirring dispersion, and other methods High performance shear thickening fluid based on 2021年3月11日 researchers [17, 21–24] pretreated the silica to chemically functionalise it before the filler is added into rubbers This work investigated an industrially feasible ball milling method to predisperse the silica in solvent and follow with high temperature silanisation in producing a pretreated silicaSilane pretreated silica produced by ball milling and its 2008年10月8日 The ball load behaviour in a pilot mill is studied under conditions of increasing particle filling, for coarse silica feed (08–18 mm) and fine silica feed (0075–03 mm), at the mill speeds of 63, 78, 88 and 98% of the criticalParticle filling and size effects on the ball load behaviour and

.jpg)

Silicon Powder Properties Produced in a Planetary Ball Mill

2020年10月1日 For example, Nilssen et al investigated the properties of silicon after ball milling with a planetary ball mill at different times, ball sizes, and speeds [76] These parameters affect the phase 2021年2月19日 The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L while the optimum speed of the ball mill is 105 parative Study on Improving the Ball Mill Process 2024年1月6日 Silica nanoparticles (SiO2 NPs) have garnered substantial attention as versatile additives in saline fluids, finding application in areas like environmental remediation, wastewater treatment Transport and retention of silica nanoparticles in glassbead 2024年9月27日 The quartz and amorphous silica were each subdivided into 200 g samples and subsequently dryground individually in a ball mill Grinding time was closely controlled to achieve a similar particles size for these pure minerals This resulted in a feed with a copper grade of 085 % and a solid concentration of 30 wt% Five different synthetic Amorphous silica effects on copper flotation: A kinetic and

.jpg)

Wet and dry grinding of coal in a laboratoryscale ball mill:

2020年1月1日 Grinding test were performed in an XMQΦ240 × 90 laboratoryscale conical ball mill (Wuan Exploring Machinery Factory, Wuhan, China) For the wet and drygrinding tests, the ball diameter, fractional ball filling, and fractional powder filling were 35 mm, 1931%, and 680% The solid concentration for the wet grinding was 70 vol %2012年12月1日 The inmill load volume and slurry solids concentration have significant influence on the ball mill product size and energy expenditure Hence, better energy efficiency and quality grind can only Optimization of inmill ball loading and slurry solids concentration concentration measurement on ballmill silica ball mill lining bricks Ball Mill Ball mills are used primary for Ball Mill buying leads for silica lining bricks اقرأ المزيد concentration measurement on ballmill silica laceindiaball and concentration mill truenorthaluminiumco2017年1月19日 In this work, the RTD measurements were carried out for a primary ball mill in closed circuit with hydrocyclones at two feed rates (ie, 280 and 230 tones per hour (t/h)) by means of tracer Measurement and Modeling of Residence Time Distribution of Overflow

.jpg)

The effect of particle sizes and solids J concentration on

2023年11月10日 the tumbling mills operations range Typical measurements for rheology charac concentration on the rheology of silica sand based suspensions by N Mangesana*, RS Chikuku*, AN Mainza*, 2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models One approach that has gained popularity is the population balance Optimization of Solids Concentration in Iron Ore Ball Milling 2021年6月28日 In the UK, 80% of the samples collected from areas near seven construction sites and five sand quarries exhibited silica concentrations of less than 30 µg m –3, but the samples from the Occupational exposure to respirable crystalline silica in 2023年9月1日 (a) Conventional ball mills, (b) Planetary ball mills; F 1: Jar's movement centrifugal force, F 2: Disk's movement centrifugal force, and F 3: Curious Force The experiment was carried out in a wet and pressurized ball milling reactor (Retsch PM Grind Control) equipped with gas pressure and temperature sensors with a measurement range of up to Intensified mineral carbonation of natural Canadian silicates

Calculate Ball Mill Grinding Capacity 911Metallurgist

2015年10月15日 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge 2024年2月26日 Abstract In analytical chemistry, colloidal silica mass concentration is usually estimated by the differential technique, which is the difference between total and dissolved silica concentrations Total silica concentration is usually obtained from inductively coupled plasma (ICP) analysis, while dissolved silica is measured by the molybdate methods This is a On the Estimation and Reporting of Colloidal Silica Mass Concentration 2014年1月1日 Either as a result of inflexible experimental setup or difficulties in measuring holdup in closedcircuit industrial mills via the RTD approach, the published correlation between holdup Effect of Slurry Solids Concentration and Ball Loading on Mill 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control

.jpg)

Effect of Ball Milling Time on the Microstructure and

2023年8月23日 The duration of ball milling greatly influences the characteristics of highsilicon–aluminum composite during the ball milling process This study examines how the microstructure, thermal conductivity, and hardness of a highsilicon–aluminum composite are affected by different ball milling times We exposed the powder to various durations of ball 2019年3月1日 Amorphous silica powder was mechanically treated by a rotating ball mill system and the surface activity of the raw and treated silica powders was measured based on the water adsorbed volume on Nonfiring ceramics: Effect of adsorbed water on surface 2014年3月2日 31 Industrial Ball Mill The ball mill utilized in the sampling survey has an inside diameter of 73 m and length of 96 m and is run in open circuit Under normal operating conditions, the mill ball loading is 30% of total mill volume, mill rotational speed is 75% of critical speed, slurry solids concentration is75%, solids feed rate is 330 Effect of Slurry Solids Concentration and Ball Loading on 2015年6月6日 Cleaning and Storing of Ball Mill Charge after the Bond Work Index Procedure is done: Add about 500 g of silica sand into the mill containing the ball charge Seal the mill Rotate for 20 revolutions to clean Empty the mill charge and sand into the ball try once grinding is complete Clean out the mill using a brush Put the lid on the millBond Work Index Procedure and Method 911Metallurgist

CHARACTERIZATION OF SILICA NANOPARTICLES

2017年5月14日 Silica nanoparticles were synthesized from rice husk ash at room temperature by using a high energy planetary ball mill The milling time and mill rotational speed were varied at four levels