Facts Figures Track Mount Mining Beneficiation Plants

.jpg)

Iron ore beneficiation: an overview ScienceDirect

2023年1月1日 This chapter briefly discusses the current scenario of the following: iron ore resources in India, iron ore mining methodology, beneficiation techniques for various ore sizes, beneficiation tests and results for a typical Indian iron ore deposit and the current operating 2021年5月20日 The following three plant types were studied: (i) an integrated DREAF plant using internal scrap, (ii) a plant using equal amounts of scrap and DRI and (iii) a plant using a smaller fraction of DRI in relation to the scrap Driving investments in ore beneficiation and 2014年7月1日 Kumba Iron Ore’s Sishen Iron Ore Mine in South Africa produces 40 Mt iron ore per annum from its beneficiation plants The ore body consists mainly of laminated and Operation and performance of the Sishen jig plantThe Mt Newman Mining Co Pty Limited Beneficiation Plant at Newman in Western Australia treats low grade iron ore mined from the Mt Whaleback Mine and separates high grade review of Operations Iron ire Beneficiation Plant

.jpg)

Process optimization of a chrome ore gravity

2020年5月19日 In this article, the performance of an operating chromite beneficiation plant is evaluated based on mineralogical characterization of samples from around the circuit This 2017年10月24日 Our testing uses state‐of‐the‐art iron ore beneficiation equipment for crushing, grinding, classification, gravity and electrostatic separation as well as high and low intensity Your iron ore beneficiation solutions Downer Group Site2023年4月30日 In practical production, the investigation of the mineral composition and processing characteristics of the raw ore, middling, concentrate, and tailings in the production Process Mineralogy SpringerLink2021年6月24日 Key regions that have benefited from our expertise in metallurgical testing, process plant design and product offerings include: Australia, Brazil, Canada, India, Russia Global Capability AusIMM

Ore Beneficiation an overview ScienceDirect Topics

To evaluate an iron ore resource, develop processing routines for iron ore beneficiation, and understand the behavior of the ore during such processing, extensive mineralogical DrNazmul Huda, in Life Cycle Assessment for Sustainable Mining, 2021 Beneficiation includes crushing, grinding, gravity concentration and flotation concentration Beneficiation is followed Beneficiation an overview ScienceDirect Topics2014年7月1日 Figures from this paper figure 1; figure 2; figure 7; figure 8; 6 Citations Citation Type Has PDF Kumba Iron Ore’s Sishen Iron Ore Mine in South Africa produces 40 Mt iron ore per annum from its beneficiation plants The ore body consists mainly of laminated and massive type haematite ore of Expand 11 PDFOperation and performance of the Sishen jig plant2016年4月13日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove Mining and Beneficiation of Phosphate Ore

.jpg)

ALAMPARA IRON ORE MINE environmentclearancenic

2014年10月18日 The manpower likely to be employed in the First Phase in Alampara Iron Ore Mine for mining, in Beneficiation Plant and related site services will be 700 The mine pit/ pits will remain active during the lease period Therefore, at present there is no proposal to backfill the pit However, after first 10 years and wherever2020年8月4日 Presently, South Australia has significant amount of rare earth elements (REE) remaining in mining tailings generated from the extraction of primary commodities such as gold, copper, and uraniumCharacterisation of Mining Tailings for the Beneficiation of 2020年4月1日 In a research article on chemical beneficiation with the subsequent gravitational beneficiation of chromecontaining slurry tailings of Donskoy OreMining and Beneficiation Plant (DOMBP), which Process optimization of a chrome ore gravity concentration plant 2023年6月30日 A Review on Process Mineralogical Characteristics and Current State of Beneficiation Process of Mount Weld Rare Earths Mine in Western AustraliaA Review on Process Mineralogical Characteristics and

Introduction to Mineral Processing or Beneficiation Sepro

13 RunOfMine Material and Minerals Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility At this point, the ore is called runofmine material because there has been no treatment performed on it There are three primary types of runofmine materials: Runofmine consisting of useful materialsLife Cycle Assessment of Copper–Gold– Lead–Silver–Zinc Beneficiation Process Dr Shahjadi Hisan Farjana, DrNazmul Huda, in Life Cycle Assessment for Sustainable Mining, 2021 CopperGoldLeadSilverZinc Beneficiation Process Beneficiation includes crushing, grinding, gravity concentration and flotation concentration Beneficiation is followed by processing Beneficiation an overview ScienceDirect Topics2021年5月20日 Figure 7 shows the cost saving in production case 2 (100 t steel from 50 t scrap + rest DRI) when SiO 2 in DRI is decreased by 2 pp and Si tot in scrap is decreased by 03 pp For an EAF plant using comparable amounts of scrap and DRI/HBI, an ore beneficiation and scrap upgrading according to the example results in a total saving of 18 USD/t steelDriving investments in ore beneficiation and scrap upgrading 2019年1月30日 Phosphate ore is an important raw material for manufacturing fertilizers and phosphorous chemical products While most of the phosphate resources cannot be directly treated as feed stock due to the low grade of P2O5 and high content of impurities In order to obtain a qualified phosphate concentrate, the beneficiation of the lowgrade phosphate ore is, Review on Beneficiation Techniques and Reagents Used for

.jpg)

Bauxite Beneficiation: An Approach to Value Addition in Mining

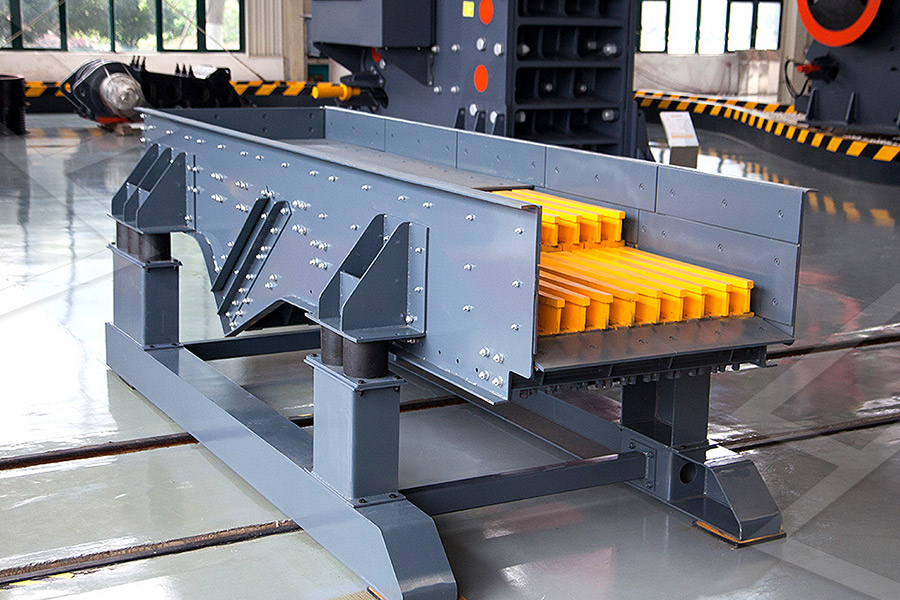

2021年7月2日 Keeping the above characteristics in view, several west coast lateritic bauxite mines of India employ dry crushing−screening process to bring down silica content from the metallurgical grade bauxite []Recently, a bauxite mine of Guinea known as AGB2A has also adopted the dry beneficiation procedure to cut down silica from about 7% to below 3%, to 2022年3月15日 The challenges facing mineral engineering today are related, on the one hand, to the increasing demand for strategic materials used in new technologies in the face of the growing share of deposits that are depleted, difficult to access and difficult to carry out the process of beneficiation on them, and, on the other hand, to the need to effectively recover these Modern Analytical Methods and Research Procedures for This is a magnetite mine that will supply 22 Mta iron ore in the first phase of development [3] The investment costs amounted to 33 to 35 bill US$ In the beneficiation plant, highpressure grinding rolls (HPGR) with downstream dry Dry beneficiation of iron ore Mineral Processing2023年1月1日 The beneficiation plant is designed to process less than 10 mm of lowgrade iron ore fines Lowgrade fines fed to the plant are scrubbed and then classified into two size fractions, that is, +05 and −05 mm utilizing vibratory screensIron ore beneficiation: an overview ScienceDirect

Mines Hindustan Zinc

2021年10月22日 With its current capacity of 6 Mt, the worldclass silverrich Sindesar Khurd Mine (SKM) is the largest underground mine in India SKM has also recently commissioned an Integrated Control Room for mine and beneficiation plant operations from a single room Minimizing Jamming By tracking its assets inside the mine using WiFi tags and LASER 2024年3月16日 Iron ore is essential in steel making; however, highgrade ores have diminished, making lowgrade ores inevitable These lowgrade iron ores need further beneficiation to upgrade the iron content Currently, traditional physical and chemical methods are utilized and are not environmentally friendly Biobeneficiation techniques have emerged as a sustainable Towards a Sustainable and Enhanced Iron Ore Recovery: Biobeneficiation 2021年12月4日 311 Group 1 – mining and beneficiation as a single stage Most of the studies considered beneficiation altogether with the mining operation For example, AwuahOffei and Adekpedjou carried out a review scrutinising the very first LCAs applied to the mining sectorThis work is focused on the extraction stage, and it mentions the beneficiation stage only when it is Life Cycle Assessment in mineral processing – a review of the 2018年7月5日 Phosphorus is common within geological materials The average continental crust contains 027% P2O5 1 Phosphorus is the primary resources to produce fertilizer and phosphorousbased products2 Phosphorus is neither substitutable nor recyclable, therefore, the total demand must be provided through the mining, beneficiation and chemical processing of [PDF] Environmental impact of phosphate mining and beneficiation

Bauxite Beneficiation: An Approach to Value Addition in Mining

2021年7月1日 The main objective of bauxite beneficiation is to lower the concentration of reactive silica, in the form of kaolinitic clay, and also to increase the alumina content2024年6月26日 Gold beneficiation projects worldwide have demonstrated the successful implementation of advanced techniques One notable case is the mine in Yanacocha, Peru, the largest gold mine in Latin America This project illustrates the application of cyanidation and other modern processes, alongside stringent environmental protocolsGold Beneficiation Techniques: Boosting Your Yield Efficiently Mining 2015年8月1日 A systematic geometallurgical assessment was carried out to track changes of mineral composition and microfabric from ore extracted at the Cavanacaw Au Mine through the entire beneficiation Geometallurgical Assessment: Beneficiation of 2023年3月17日 Production status (overview) of the mine and beneficiation plant: production history, process evolution, production scale, products and output of the beneficiation plant, etc 2 Ore properties: the source of ore during the examination period, the proportion of ore and ore properties at different outcrop locations, multielement analysis Mineral Beneficiation Plant Process Examination Mining Pedia

Minerals Special Issue : Recent Trends in

2019年4月30日 Recent Trends in Phosphate Mining and Beneficiation and Related Waste Management Show Figures Figure 1 12 pages, 4644 KiB ultrafine particles less than 20 µm prior to concentration by flotation is a 2023年5月24日 Apatite ore plays a critical and irreplaceable role in fertilizer production and is being upgraded in quality in northern Vietnam The old tailing of the Bac Nhac Son beneficiation plant (Vietnam) has a significant apatite amount in the form of coarse unliberated particles These millions of tons of tailing ore have 6–8% of P2O5 content, which can be retreated to provide A Study on Apatite Recovering from the Tailing of the BacRio Tinto Iron Ore's lowgrade ore beneficiation plant in the Pilbara was commissioned in 1979 Initial engineering, design, and construction were undertaken by KBR (Kellogg Brown and Root) and Minenco (RTIO information provided to author, 2013) Figure 106 Mount Tom Price DMS plants Like the Sishen plant, the Mount Tom Price plant Ore Beneficiation an overview ScienceDirect Topics2023年4月30日 Besides, the workers of beneficiation process mineralogy should move from the laboratory to the mine to directly engage with the mining enterprise, investigate the production process of beneficiation plant, and diagnose and analyze the ore beneficiation process, so as to facilitate technological advancement of mining enterprise and realize Process Mineralogy SpringerLink

Sustainable phosphate mining: Enhancing efficiency in mining

2024年5月1日 The relationship between mining and sustainability has been an area of growing interest in recent decades Some papers have criticized the concept of “sustainable mining”, alleging that it is sometimes used for the marketing and publicity purposes of mining companies (Kirsch, 2010; Whitmore, 2006)However, other authors have defended sustainable mining for 2022年4月1日 iron ore beneficiation Today, we are recognised by customers worldwide as the 'go to' partner for fine iron ore beneficiation solutions across the project lifecycle Customers call us when they need fast, cost effective beneficiation solutions to lower costs, convert tailings into revenue or design beneficiation plantsWorld leader in fine iron ore beneficiation Mineral 2022年1月21日 To improve the sustainable management of phosphorus, numerous LCA studies, using primary data, have been conducted for phosphorus recovery technologies from wastewater, but not for phosphate rock miningThis article addresses this issue by conducting a cradle to gate assessment of beneficiated phosphate rock production using primary data This Cradletogate life cycle assessment of beneficiated Bauxite deposit: geometrically defined space, geological unit composed of the bauxite body and its associated formationsIn practice they are the subjects of the mining operation Duricrust—cuirassé: Iron rich (Fe 2 O 3 % attains as much as 60–80%) layer developed on the topmost level of the laterite section in 02–03 m thickness It is mostly laminar or scoriaceous Bauxite: Geology, Mineralogy, Resources, Reserves and Beneficiation

.jpg)

Mining and Concentration: What Mining to What Costs and

2014年1月1日 The Mining Node’s focus in the phosphate life cycle includes mine planning and development, extraction, primary processing of ore to produce phosphate rock (PR) concentrates and transportation to a port or processing plant (Scholz et al 2011)Mine planning and development is initiated following the discovery and evaluation of a resource during the 950tph iron ore beneficiation wet processing project in South Australia Learn more about this awardwinning CDE and Simec Mining project +44 28 8676 7900 Language Applications Sand Aggregates 950tph Iron Ore Simec Mining 950tph Iron Ore Beneficiation 2023年9月14日 The fluorite beneficiation process involves several stages, each critical for achieving optimal results These stages include exploration and resource assessment, ore sampling and characterization, laboratoryscale A Comprehensive Guide to Fluorite Beneficiation Australia is a major resourcerich country with the 6th largest rare earth (RE) reserves in the world and is operating the Mount Weld mine, the highest REE grade mine in the world Although a beneficiation plant, which performs crushing, desliming, flotation, andA Review on Process Mineralogical Characteristics and

.jpg)

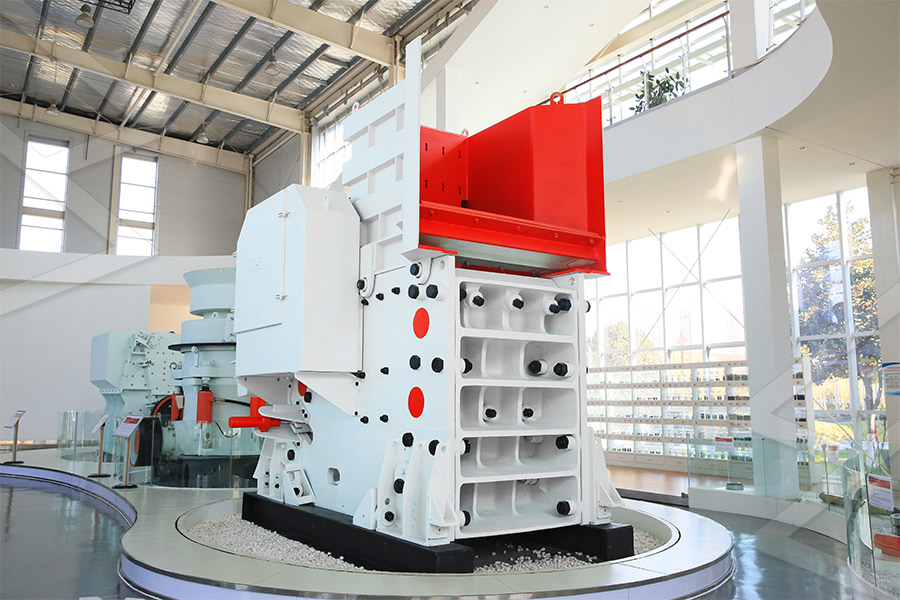

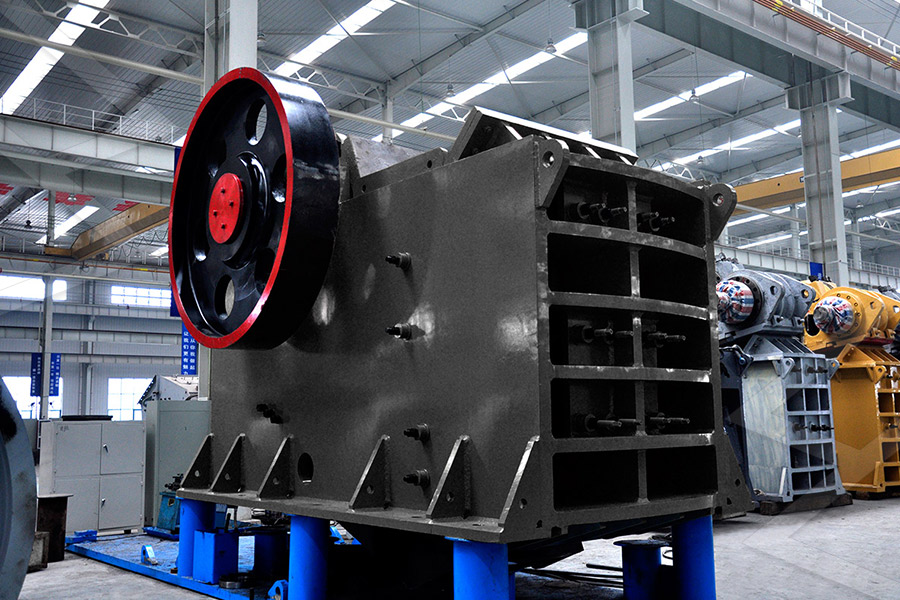

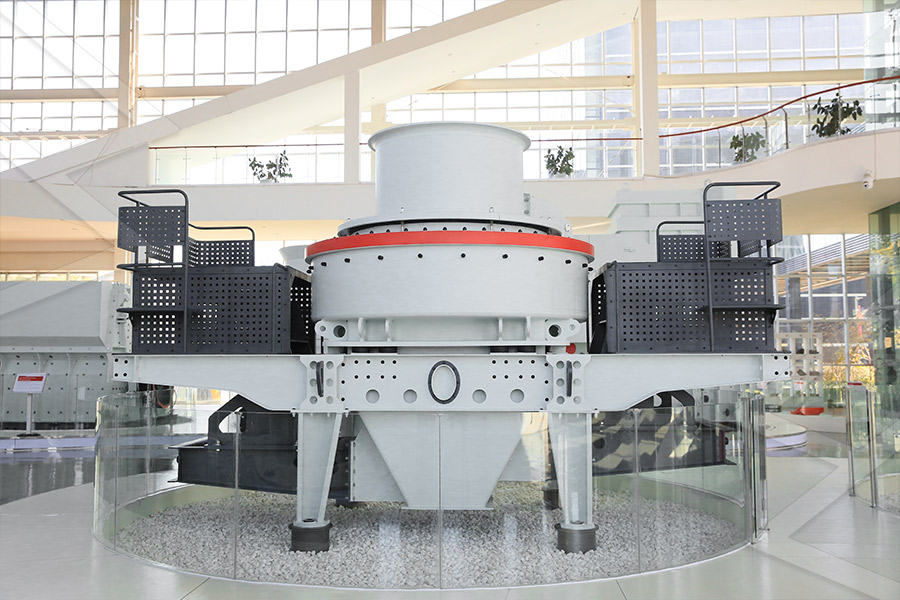

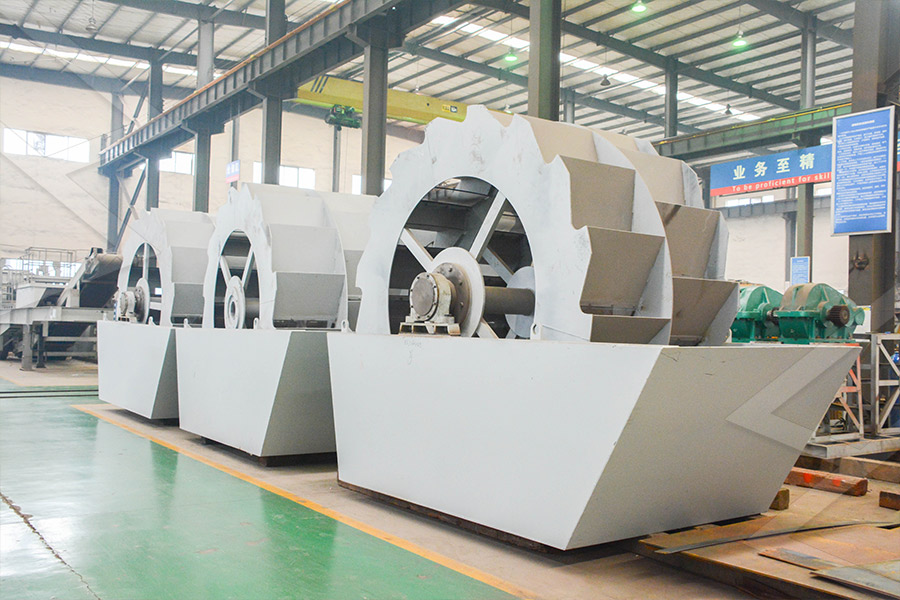

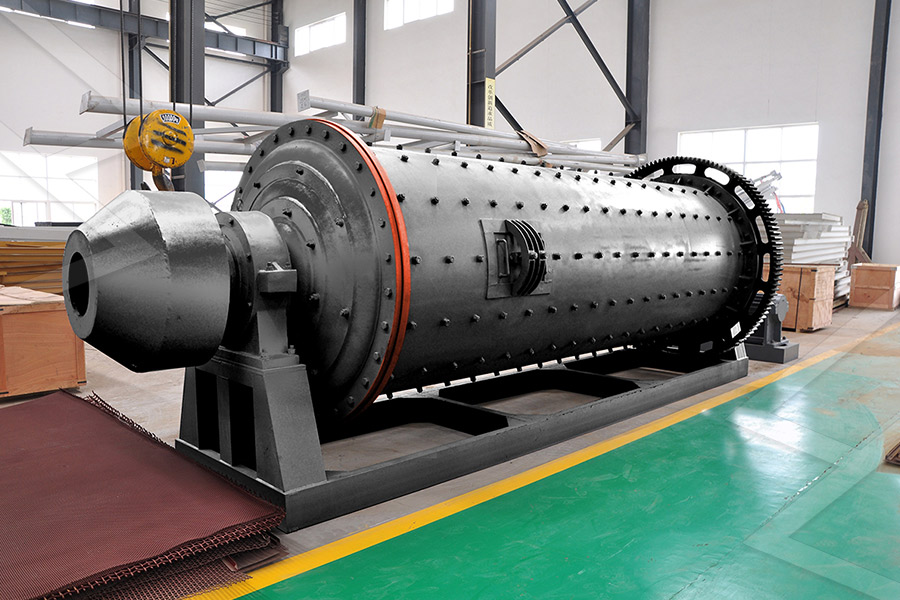

Beneficiation Plant Construction Design FraserLever

The mine at Mt Moss, north west of Townsville, mines predominantly iron ore However there is also a copper and zinc deposit at Mt Moss The work carried out by FraserLever has been for the iron ore beneficiation plant design and construction which has included a 3 stage crushing plant, grinding mills and both dry and wet beneficiation plantsBeneficiation plant discard is backfilled into the minedout portion of the open pit while slimes are pumped to a specially designed cyclic pond system from where it is later reclaimed and blended in small quantities with the power station coal produced Figure 11: Grootegeluk mine Grootegeluk history Table 20: Grootegeluk operation Exxaro Resources Limited Consolidated Mineral Resources Grootegeluk comprises one openpit mine which includes two overburden benches, nine RoM benches and three interburden benches RoM is transported to the Grootegeluk beneficiation complex via hauling trucks and conveyor belts The beneficiation complex consists of eight plants producing several different coal products to client specificationsExxaro Resources Limited Consolidated Mineral Resources 2021年1月31日 coalbeneficiation plant at Grootegeluk* by J GILLlLANDt Pr Eng BSc Blng (Mech) SAAVNK SYNOPSIS The Grootegeluk coalbeneficiation plant was erected in the Waterberg coalfield, near Ellisras in the Transvaal, to supply Iscor's steelworks with a predetermined tonnage of coking coal in accordance with strict quality requirementsThe planning and establishment of the coal

Rare Earth Beneficiation and Hydrometallurgical Processing

2016年2月11日 Each rare earth deposit is unique and is always composed of a variety of minerals For example, the Baiyun Obo deposit, the largest rare earth mine in production in China, contains bastnaesite, monazite, fluorite, magnetite, barite, calcite, quartz, feldspar, etc (Cheng et al 2007a, b)In order to make a rare earth project economically feasible, a series of ore 2023年1月1日 A typical coal train travels over 800 miles from a mine to a plant or terminal, carrying about 4800 tons of coal in 600 cars Figure 11, Figure 12 show the process flow diagrams of heavy media baths in Typical results in a coal beneficiation plant using spirals to treat fine coal indicated very little deterioration in performance with Coal beneficiation: theory and practice ScienceDirect